Amikor felkeres egy webhelyet, az információkat tárolhat vagy kérhet le az Ön böngészőjében, többnyire cookie-k formájában. Ezek az információk szólhatnak Önről, az Ön preferenciáiról vagy az Ön eszközéről, és többnyire arra szolgálnak, hogy a webhely az elvárásoknak megfelelően működjön. Az információk általában nem azonosítják Önt közvetlenül, de személyre szabottabb internetes élményt nyújthatnak.

Mivel tiszteletben tartjuk a magánélethez való jogát, dönthet úgy, hogy nem engedélyez bizonyos típusú sütiket. Bizonyos típusú cookie-k letiltása azonban hatással lehet az oldallal kapcsolatos élményére és az általunk kínált szolgáltatásokra.

Engedélyezi a:-t

Feltétlenül szükséges cookie-k (kötelező)

Ezek a cookie-k szükségesek ahhoz, hogy Ön böngésszen weboldalunkon és használhassa annak alapvető szolgáltatásait, és nincs szükség az Ön hozzájárulására. Ezek a cookie-k lehetővé teszik számunkra, hogy a weboldal alapvető funkcióit (fiókhozzáférés, használt nyelv, lejátszási sorrend, fizetés) kínáljuk Önnek. stb.), valamint személyazonosság-ellenőrzésre és biztonságra is használható. Ha letiltja őket, nem tudjuk teljesíteni az alapvető kérést.

Ezek a cookie-k névtelen információkat gyűjtenek az Ön online működési viselkedéséről, amelyek segítenek nekünk a webhely felépítésében. Ha elutasítja ezeket a sütiket, előfordulhat, hogy nem fogja tudni használni webhelyeink és szolgáltatásaink egyes funkcióit.

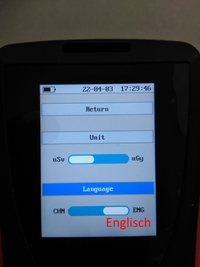

Ezek a sütik lehetővé teszik számunkra, hogy emlékezzünk az Ön preferenciáival kapcsolatos döntéseire, például arra, hogy melyik nyelvet részesíti előnyben. Ha elutasítja ezeket a sütiket, úgy érezheti, hogy a webböngészés hatékonysága csökkent.

Ezek a sütik személyre szabott tevékenységeket végeznek az Önt érdeklő termékek és szolgáltatások hirdetésére. Ha elutasítja ezeket a sütiket, továbbra is olyan hirdetéseket fog látni, amelyek nem igazán relevánsak az Ön érdeklődéséhez vagy keresletéhez.